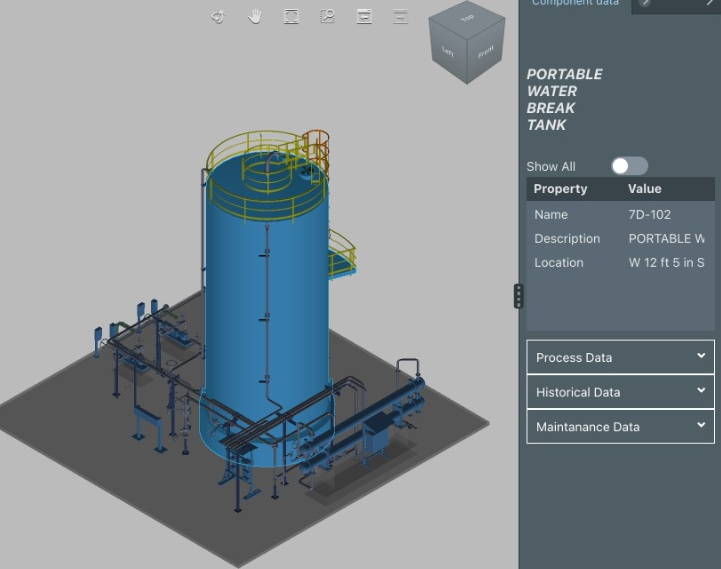

Digital Twin for efficient Operations and Maintenance

In principle, a digital twin is a virtual representation of the key attributes of a physical object or process that can be tracked and updated along the lifecycle to achieve design and operational efficiencies.

Ceone, in collaboration with market leaders, provide the digital twin platform-based solutions (for Discrete and Composite level).

We do understand that many of the industry players are at various stages of digital maturity and our solutions try to address the requirements based on existing maturity across the asset life cycle.

Ceone has strategic partnership with Bentley for its Digital Twin platform iTWIN. With a team of certified digital twin developers, exposure to other digital products including PLANTSIGHT, Ceone can enable organisations to start their Digital transformation journey.